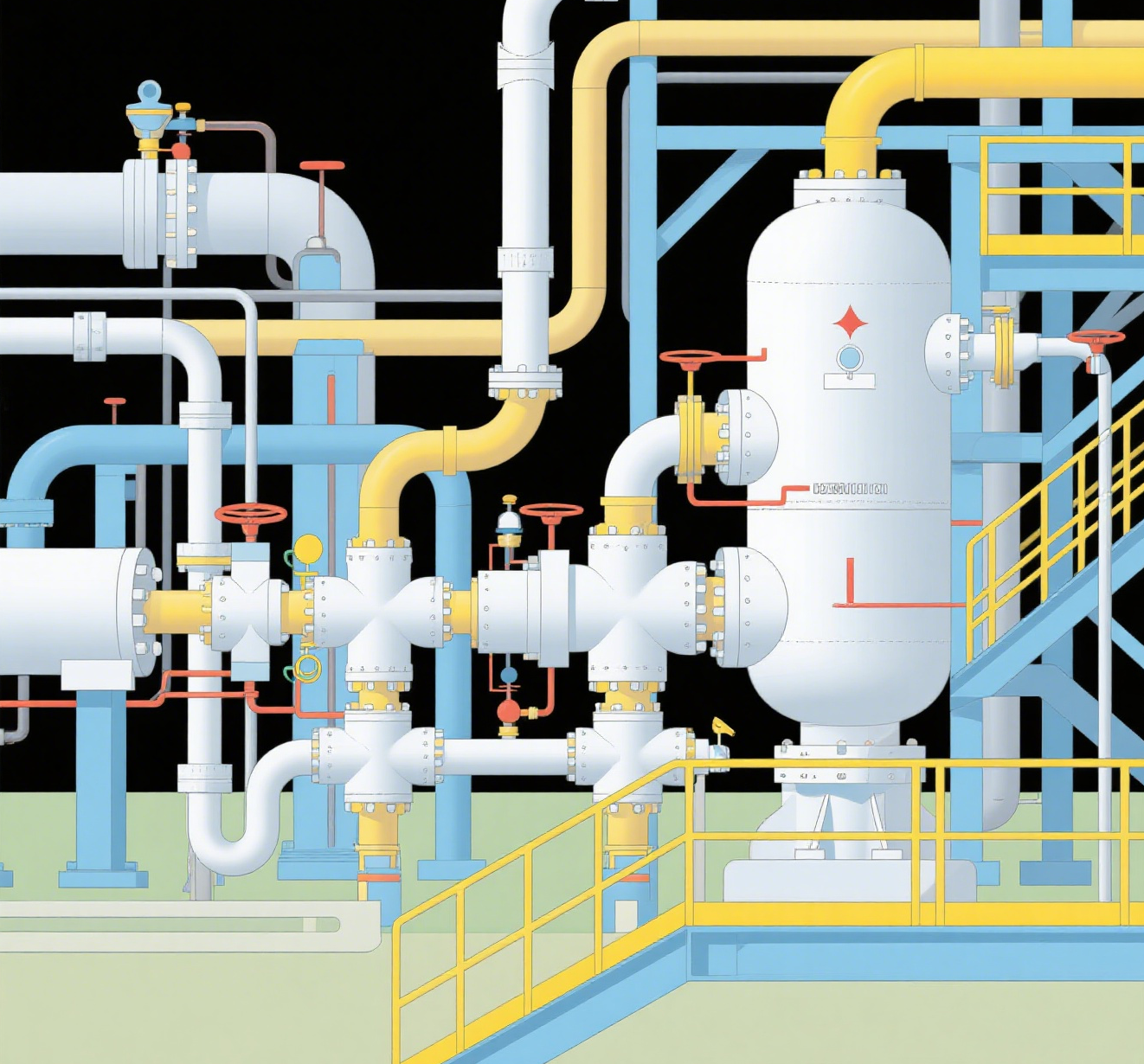

Pre-Treatment Phase of Natural Gas Liquefaction

Acid Gas Removal Techniques

Acid gases such as CO₂ (carbon dioxide) and H₂S (hydrogen sulfide) are removed first in order to avoid pipeline corrosion and for safety reasons. Amine-based absorption systems represent 68% share in the world LNG plants (GasTech 2023) and employ solvents such as MDEA that can react chemically with acidic components. Membrane separation and cryogenic distillation are alternatives where the contaminant concentrations in the gas stream are lower. These procedures allow the methane to be purified to a methane concentration greater than 98.5% and thereby minimize the risk of freezing during cryogenic race.

Dehydration Methods for Pipeline-Quality Gas

Residual water vapor is further lowered to <0.1ppm by molecular sieve adsorbents such as aluminosilicate beads. This is to avoid formation of ice crystals during liquefaction at -260°F (-162°C), as ice crystals could damage valves and heat exchangers. In two-tower adsorption systems, the towers switch between adsorption and regeneration and the material is processed continuously. Glycol drying works well for upstream separation drying, but is not suitable for the extremely dry nature necessary for LNG specifications.

Mercury Removal Protocols

Hg< 0.01 μg/m³ is sequestered by sulphur-impregnated activated carbon beds to avoid aluminum heat exchanger embrittlement. One-time use metal sulfide beds are regular in 82 per cent of Arctic LNG ventures for their single-cycle assurance in sub-zeroing conditions (CryoGas Journal 2023). Real-time reading using atomic fluorescence spectroscopy. to comply with ISO 14912 purity standard.

Nitrogen Removal in LNG Liquefaction

Cryogenic Distillation Process

The cryogenic distillation process cools natural gas to -200°F to isolate nitrogen through fractional condensation. As methane remains gaseous at these temperatures, nitrogen liquefies first due to its higher condensation point. Multi-stage distillation columns achieve <3% nitrogen content in final LNG products, with separation efficiencies exceeding 98% in modern plants.

Impact on LNG Calorific Value

Excess nitrogen (≥5% volume) reduces LNG’s heating value by up to 25%. Maintaining ≤1% nitrogen concentration ensures compliance with ISO 6976 standards (1,050-1,150 BTU/ft³). LNG with optimized nitrogen content demonstrates 18% more efficient combustion compared to high-nitrogen blends, a critical factor for power plants requiring consistent fuel performance.

Core Liquefaction Process of Natural Gas

Propane-Mixed Refrigerant (C3MR) Cycles

C3MR (propane-mixed refrigerant) cycle is the most advanced LNG plant which can reach 20-30% higher energy efficiency than the single-refrigerant system by employing the pre-cooling of propane together with mixed refrigerants composed of nitrogen, methane, and hydrocarbons. Cascade cooling Although not a large innovation, TC could achieve Ranger saps by cooling feed gas down to -40°F with propane so that the meth- ane can be liquefied down to -260°F with mixed refrigerants. A 2024 simulation research conducted by Bassioni et al. confirmed that the optimized C3MR schemes can reduce energy consumption to 850 kWh/t of LNG.

Temperature Optimization at -260°F

-260°F (-162°C) is achieved by carefully defining the refrigeration load, matched by state of the art heat exchangers. State-of-the-art plants are already using three stage compression cycles in combination with aluminum brazed-plate heat exchangers (BPHEs) to lower temperature oscillations to less than ±2°F. The 2018 vortex search algorithm benchmark recorded a 12% efficiency rise by optimizing of the refrigerant in real-time. Boil-Off Gas (BOG) generation is controlled with two control systems, which keep the tank pressure below 25 kPa.

LNG Storage Infrastructure Requirements

Double-Containment Tank Engineering

Current LNG storage is based on dual-containment tanks built with an inner and an outer container and the space between them is filled with insulating materials. The inner vessel is made of 9% nickel steel with a carbon-equivalent hardness less than 237 — maintaining cooled temperatures at -260°F, while the outer shell serves as a pressure shield to contain the liquid if there’s a departure from a stable condition. State-of-the-art insulation material technology has limited the heat input to ≤0.08 W/m²·K, which leads to small/zero boil-off gas (BOG) creation.

Boil-Off Gas Re-Liquefaction Systems

BOG management systems recover 98% of evaporative gas using cascade refrigeration cycles paired with cryogenic compressors. Standard configurations reduce BOG volumes from 0.15% to ≤0.03% daily through multi-stage liquefaction. Advanced plants employ closed-loop nitrogen expanders to cool BOG from 45°F to -260°F, achieving 92% energy efficiency compared to conventional Joule-Thompson valves.

Quality Control in Natural Gas Liquefaction

Composition Monitoring Technologies

Material composition analysis is done continuously to guarantee that natural gas quality meets such tight limits as >85%(v/v) methane and impurities <50 ppm CO₂ and <4 ppm H₂S before liquefaction. Contemporary plants use gas chromatographs and cavity ring-down spectrometers to make 240+ measurements of hydrocarbon dew points and sulfur on a daily basis. In the 2023 Global LNG Quality Report, sites with real-time mass spectrometry cut off-specification batches by 67%.

ISO 28460 Standards Compliance

Adherence to ISO 28460:2019 guarantees LNG quality consistency across international trades through standardized sampling protocols. The framework requires:

- Minimum 8 composite samples per marine loading operation

- ±0.25% maximum variance in methane number calculations

- Documented mercury content verification (<0.01 μg/m³)

A 2022 benchmark study shows ISO-certified terminals resolve 92% of custody transfer disputes within 24 hours versus 58% at non-compliant facilities.

FAQ

What are the key steps in the pre-treatment phase of natural gas liquefaction?

The key steps include acid gas removal, dehydration, and mercury removal to purify the natural gas before it's liquefied.

How is nitrogen removed during the LNG liquefaction process?

Nitrogen is removed through a cryogenic distillation process that cools the natural gas to isolate nitrogen.

What are the main technologies used for composition monitoring in natural gas liquefaction?

The main technologies include gas chromatographs, cavity ring-down spectrometers, laser absorption, and cryogenic sampling.

Why is nitrogen removal important in LNG production?

Removing excess nitrogen is important to maintain the LNG's heating value and ensure consistent combustion efficiency, especially in power plants.